HVAC Pumps Supplier

Are you in search of premium centrifugal pumps that are perfectly suited to your industrial requirements? As your dependable HVAC pumps supplier in India, we offer an extensive selection of cutting-edge pumping solutions designed to optimize your operations. Elevate your industrial performance with our superior HVAC pumps. Contact us today to explore the full range of our innovative pumping solutions!

Elevate your HVAC system’s efficiency with our cutting-edge HVAC pumps. As a leading HVAC pump supplier, we specialize in providing high-performance pumps designed to optimize heating, ventilation, and air conditioning processes. Our pumps are engineered for reliability, energy efficiency, and precise temperature control. Whether you need solutions for residential or commercial applications, we offer a comprehensive range of HVAC pumps tailored to your specific needs. Trust in our expertise to enhance your HVAC system’s performance, reduce energy costs, and ensure year-round comfort. Choose us as your HVAC pump supplier for innovation and excellence in HVAC technology.

Recirculation Pumps

Condenser water pumps

TES Pumps

Vertical inline Pumps

Split Case Pumps

Regenerative Turbines

Recirculation Pumps:

Recirculation Pumps

Recirculation pumps, also known as circulator pumps or recirculating pumps, are a type of centrifugal pump designed for closed-loop systems. Their primary function is to continuously circulate water or another heat transfer fluid within an HVAC system. These pumps are commonly used in both residential and commercial settings.

Working Principle:

Recirculation pumps operate by using a rotating impeller driven by a motor. As the impeller spins, it imparts kinetic energy to the fluid, creating high-pressure areas at the edges and a low-pressure area at the center. This pressure difference forces the fluid outward into the pump housing. The pumped fluid is then directed into the HVAC system’s pipes, where it circulates through heating or cooling components. Many recirculation pumps come with variable speed drives (VFDs) for precise flow control, improving energy efficiency.

Usage:

Commonly used in hydronic heating and cooling systems to ensure even temperature distribution.

Specifications

| Flow Rate | 10 – 150 gallons per minute (LPM) |

| Head Pressure | 10 – 50 feet |

| Motor Power | 0.25 – 10 horsepower (HP) |

| Pipe Connection Size | 1/2″ – 2″ NPT (National Pipe Thread) |

| Voltage | 120V or 240V AC, single-phase or three-phase |

| Material of Construction | Stainless steel, cast iron, or bronze |

| Control Options | Manual, automatic, or variable speed control with VFD |

| Efficiency | High-efficiency |

| Operating Temperature | -20°F to 250°F (-29°C to 121°C) |

Condenser water pumps

Condenser water pumps

Condenser water pumps are specialized centrifugal pumps designed for the specific task of moving water through the condenser portion of an HVAC system. These pumps play a pivotal role in the heat rejection process, allowing the system to efficiently transfer heat from the building’s interior to the outside environment.

Working Principle:

The condenser water pump motor spins an impeller in the pump, which adds energy to the water, making high-pressure areas at the edges and low-pressure areas in the middle. This pressure difference pushes the water out into the system. The high-pressure water goes to the condenser coils, where it takes heat from the refrigerant, turning it from a gas to a liquid. After cooling down, the water goes back to the pump to start the process again.

Usage:

Condenser water pumps are primarily used in chiller plants and large-scale HVAC systems. Their role is vital for achieving effective cooling in air conditioning systems, particularly in commercial and industrial settings.

Specifications

| Flow Rate | 50 – 1500 gallons per minute (LPM) |

| Head Pressure | 40 – 200 feet |

| Motor Power | 10 – 100 horsepower (HP) |

| Pipe Connection Size | 2″ – 10″ NPT (National Pipe Thread) |

| Voltage | 208V, 230V, 460V AC, three-phase |

| Material of Construction | cast iron or bronze |

| Control Options | Manual, automatic, or variable speed control with VFD |

| Efficiency | High-efficiency |

TES Pumps

TES Pumps

TES (Thermal Energy Storage) pumps are essential components in thermal energy storage systems. These pumps facilitate the efficient storage and release of thermal energy, contributing to energy management and sustainability.

Working Principle:

TES pumps operate by circulating a heat transfer fluid, such as water or specialized fluids, to and from thermal storage tanks. This fluid absorbs and stores excess thermal energy during off-peak periods and releases it when needed for heating or cooling.

Usage:

TES pumps are integral to HVAC (Heating, Ventilation, and Air Conditioning) systems and industrial processes where load shifting and energy conservation are crucial. They are commonly used in commercial buildings, district energy systems, and renewable energy applications.

Specifications

| Flow Rate | 50 – 500 gallons per minute (LPM) |

| Head Pressure | 10 – 100 feet |

| Motor Power | 5 – 50 horsepower (HP) |

| Pipe Connection Size | 2″ – 6″ NPT (National Pipe Thread) |

| Voltage | 208V, 230V, 460V AC, three-phase |

| Material of Construction | Stainless steel, cast iron, or specialized material |

| Control Options | Manual, automatic, or variable speed control with VFD |

| Efficiency | High-efficiency models available for energy savings |

| Operating Temperature | -20°F to 250°F (-29°C to 121°C) |

End-Suction pumps

End-Suction pumps

End-suction pumps are a common type of centrifugal pump used in various industries and applications. They are characterized by having a single inlet and a single outlet, making them versatile and easy to install.

Working Principle:

End-suction pumps work on the principle of centrifugal force. A motor-driven impeller inside the pump housing rotates, creating a centrifugal force that pushes fluid toward the outer edges of the impeller. This action generates suction at the center of the impeller, drawing fluid into the pump. The rotating impeller then propels the fluid outward, increasing its pressure as it exits through the outlet.

Usage:

End-suction pumps are widely employed in various applications, including water supply, irrigation, HVAC systems, industrial processes, and wastewater handling. They are known for their reliability and ease of maintenance, making them a popular choice for many fluid transfer tasks.

Specifications

| Flow Rate | 50 – 5,000 gallons per minute (LPM) |

| Head Pressure | 20 – 500 feet |

| Motor Power | 1 – 200 horsepower (HP) |

| Pipe Connection Size | 1″ – 12″ NPT (National Pipe Thread) |

| Voltage | 208V, 230V, 460V AC, three-phase |

| Material of Construction | Cast iron, bronze, stainless steel, or other materials |

| Control Options | Manual or automatic control options |

| Efficiency | High-efficiency models available for energy savings |

| Operating Temperature | -20°F to 250°F (-29°C to 121°C) |

Vertical inline Pumps

Vertical inline Pumps

Vertical inline pumps are a type of centrifugal pump known for their space-saving design and ease of installation. They have a vertically aligned configuration, where the motor and pump are integrated into a single unit, making them ideal for applications with limited floor space.

Working Principle:

The working principle of vertical inline pumps is based on centrifugal force. An electric motor drives the impeller, which is positioned vertically within the pump casing. As the impeller rotates, it creates a centrifugal force that draws fluid into the center of the impeller. The fluid is then expelled radially outward, increasing in pressure as it exits through the discharge outlet.

Usage:

Vertical inline pumps find extensive use in various applications, including water supply systems, HVAC (Heating, Ventilation, and Air Conditioning), pressure boosting, industrial processes, and municipal water treatment. Their compact design and efficient operation make them suitable for environments where space is at a premium.

Specifications

| Flow Rate | 50 – 1,000 gallons per minute (LPM |

| Head Pressure | 30 – 200 feet |

| Motor Power | 1 – 100 horsepower (HP) |

| Pipe Connection Size | 2″ – 8″ NPT (National Pipe Thread) |

| Voltage | 208V, 230V, 460V AC, three-phase |

| Material of Construction | Cast iron, stainless steel, or other materials |

| Control Options | Manual, automatic, or variable speed control with VFD |

| Efficiency | High-efficiency models available for energy savings |

| Operating Temperature | -20°F to 250°F (-29°C to 121°C) |

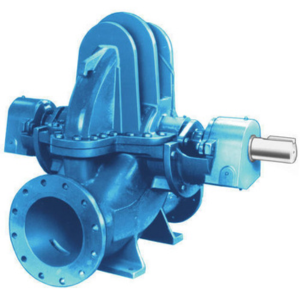

Split Case Pumps

Split Case Pumps

Split case pumps are a type of centrifugal pump designed with a split casing, allowing easy access to internal components for maintenance. They are known for their robust construction and reliability in various industrial and municipal applications.

Working Principle:

Split case pumps operate based on the centrifugal force principle. A motor-driven impeller rotates within the split casing, drawing fluid into the pump through the suction inlet. As the impeller spins, it imparts kinetic energy to the fluid, creating high-pressure regions at the periphery. The fluid is then expelled through the discharge outlet at increased pressure.

Usage:

Split case pumps are widely used in applications where high flow rates and high-pressure capabilities are required. Common applications include water supply for municipal systems, industrial processes, agriculture, and HVAC systems. Their design makes them suitable for tasks such as water distribution, circulation, and transfer in large-scale operations.

Specifications

| Flow Rate | 200 – 10,000 gallons per minute (LPM |

| Head Pressure | 50 – 500 feet |

| Motor Power | 10 – 500 horsepower (HP) |

| Pipe Connection Size | 4″ – 24″ NPT (National Pipe Thread) |

| Voltage | 208V, 230V, 460V AC, three-phase |

| Material of Construction | Cast iron, stainless steel, or other materials |

| Control Options | Manual or automatic control options |

| Efficiency | High-efficiency models available for energy savings |

| Operating Temperature | -20°F to 250°F (-29°C to 121°C) |

Regenerative Turbines:

Regenerative Turbines:

Regenerative turbines are a type of energy conversion device used to extract mechanical work from a flowing fluid, typically steam or liquid, through a specific design that harnesses the fluid’s kinetic energy.

Working Principle:

Split case pumps operate based on the centrifugal force principle. A motor-driven impeller rotates within the split casing, drawing fluid into the pump through the suction inlet. As the impeller spins, it imparts kinetic energy to the fluid, creating high-pressure regions at the periphery. The fluid is then expelled through the discharge outlet at increased pressure.

Usage:

Regenerative turbines find application in a range of industries, including power generation, chemical processing, and water desalination. They are particularly useful in situations where high efficiency and compact design are essential. Common applications include small-scale power generation, low-flow fluid pumping, and processes that involve the controlled release of energy.