A centrifugal pump is one of the most essential components in an industrial processing plant. The proper selection of a centrifugal pump from various available types is critical for optimal plant performance. These pumps are widely utilized across multiple industries, including oil refineries, petrochemical plants, power stations, agriculture, food processing, and even residential buildings for water supply.

In industrial settings, centrifugal pumps play a vital role in transporting liquids between different pieces of equipment. They are also used for long-distance fluid transfer through cross-country pipelines and for applications requiring high-pressure conditions, such as boiler feedwater systems.

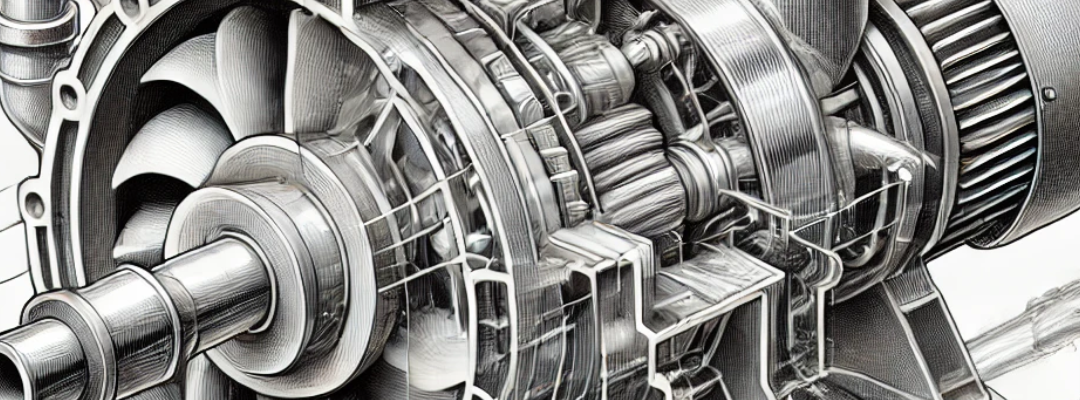

This article delves into the working principle, key components, and critical factors that influence the operation of centrifugal pumps.

What is a Centrifugal Pump?

A centrifugal pump is a type of rotating mechanical device that converts kinetic energy into pressure energy, enabling fluid movement. It operates using an impeller, which is powered by an external energy source such as an electric motor, diesel generator, or turbine.

The pump’s function is straightforward: liquid enters through the suction nozzle, passes through the rotating impeller vanes, and is expelled by centrifugal force through the discharge nozzle. The volute casing helps direct and control the fluid flow while also contributing to the pressure buildup.

The functioning rule of the pump is the change of energy. Allude to the diagram that makes it simpler for this whole energy transformation measure straightforward.

Basic Working Principle:

- Suction Phase: The liquid enters the pump through the suction nozzle.

- Impeller Rotation: The fluid is drawn into the impeller through its eye, where it gains velocity.

- Energy Conversion: The rotating impeller imparts kinetic energy to the fluid.

- Discharge Phase: The high-speed liquid enters the volute casing, where velocity decreases while pressure increases.

- Fluid Exit: The pressurized liquid exits the discharge nozzle and moves to the designated process system.

The diagram below illustrates the step-by-step process of fluid movement inside a centrifugal pump.

(Insert an annotated diagram showing fluid movement from suction to discharge)

Key Components of a Centrifugal Pump

Understanding the critical components of a centrifugal pump helps in troubleshooting and optimizing performance. The main parts include:

- Impeller: The rotating part that imparts kinetic energy to the fluid.

- Volute Casing: A curved funnel that converts velocity into pressure energy and directs the fluid flow.

- Shaft & Bearings: Provides support for the impeller and facilitates smooth rotation.

- Suction & Discharge Nozzles: Entry and exit points for fluid flow.

- Mechanical Seal or Gland Packing: Prevents leakage along the shaft.

- Motor or Engine: Provides external power to drive the pump.

Factors Affecting Centrifugal Pump Performance

Several factors influence the efficiency and effectiveness of a centrifugal pump. These include:

1. Suction Pressure

- If the pressure at the suction is too low, it may lead to cavitation, which can cause severe damage to the impeller.

- Proper Net Positive Suction Head (NPSH) must be maintained to avoid cavitation-related issues.

2. Flow Rate at Suction

- A steady flow of liquid at the suction is necessary for the pump to function as designed.

- Insufficient suction flow can reduce discharge flow, leading to inefficiencies or even pump failure.

- Dry running should always be avoided as it can cause severe internal damage to the pump.

3. Viscosity of the Liquid

- Centrifugal pumps perform best with low-viscosity fluids such as water, chemicals, or light oils.

- Higher viscosity fluids require specially designed pumps as they increase resistance and power consumption.

4. Vapor Pressure of the Fluid

- If the process liquid has a low vapor pressure, it increases the risk of cavitation.

- Ensuring adequate pressure within the system at all times is critical to prevent vaporization inside the pump.

5. Temperature and Density of the Liquid

- Higher liquid density increases the required power input for fluid movement.

- Extreme temperatures may affect seal integrity and impeller efficiency, requiring temperature-resistant materials.

Best Practices for Efficient Pump Operation

To maximize the efficiency and lifespan of a centrifugal pump, consider the following:

- Proper Priming – Ensure the pump is adequately primed before startup to avoid air entrapment.

- Regular Maintenance – Inspect impellers, seals, and bearings for wear and tear.

- Monitor Pressure & Flow Rates – Keep an eye on differential pressure and flow rates to detect anomalies.

- Use the Right Pump for the Right Application – Select the appropriate pump type based on the fluid properties and operating conditions.

- Implement Vibration & Temperature Monitoring – Helps detect early signs of mechanical failures.