When it comes to fluid handling in industrial and urban settings, selecting the right pump type is crucial for efficiency, reliability, and cost-effectiveness. Both centrifugal and positive displacement pumps play essential roles, but their mechanisms, applications, and fluid handling capabilities differ significantly.

This guide provides an in-depth comparison to help you determine which pump type best suits your operational needs.

Fluid Transfer Mechanisms

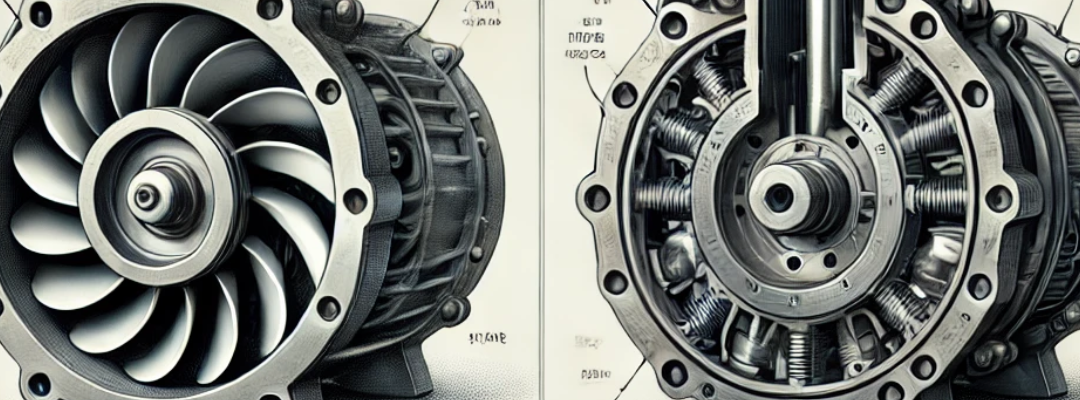

Both centrifugal and positive displacement pumps move fluids from an inlet to an outlet, but they function differently in how they create flow and pressure:

- Positive Displacement Pumps: These pumps operate by trapping a fixed volume of fluid in a chamber and then forcing it out using mechanical pressure. This ensures a constant flow rate regardless of pressure changes.

- Centrifugal Pumps: These pumps rely on a rotating impeller that accelerates the fluid outward, converting mechanical energy into kinetic energy. The pressure generated depends on fluid velocity rather than displacement.

Key Takeaway:

- For consistent flow under varying pressures → Use a Positive Displacement Pump.

- For continuous, high-volume fluid movement → Use a Centrifugal Pump.

Types of Fluids Handled

The nature of the fluid being transported plays a significant role in pump selection.

Positive Displacement Pumps: Ideal for High-Viscosity and Shear-Sensitive Fluids

- Handles highly viscous fluids efficiently (e.g., oils, syrups, sludge).

- Can pump shear-sensitive materials that degrade under force (e.g., food products, emulsions).

- Can operate dry intermittently and start without requiring liquid priming.

Centrifugal Pumps: Best for Low-Viscosity, Free-Flowing Fluids

- Ideal for water, fuel, light chemicals, and low-viscosity oils.

- Not suitable for viscous fluids due to increased frictional losses.

- Requires priming before startup to ensure proper operation.

Key Takeaway:

- Use positive displacement pumps for thick, sensitive, or intermittent-flow applications.

- Choose centrifugal pumps for clear, low-viscosity fluids requiring continuous flow.

Key Performance Differences

The performance of these pumps varies based on flow rate and pressure adaptability:

| Factor | Positive Displacement Pumps | Centrifugal Pumps |

| Flow Rate Consistency | Maintains a constant flow, regardless of pressure changes. | Flow rate varies with pressure. |

| Efficiency at Different Viscosities | Better for thick fluids, as flow improves with increasing viscosity. | Struggles with high-viscosity fluids due to friction. |

| Suction Lift Capability | Can operate without liquid priming, making it useful for dry start applications. | Requires priming before starting to prevent damage. |

Key Takeaway:

- For applications where consistent flow is crucial, positive displacement pumps are ideal.

- For handling large volumes efficiently with minimal resistance, centrifugal pumps are the best choice.

Common Applications

Each pump type has distinct applications based on fluid type, pressure, and flow rate requirements:

Centrifugal Pumps: Best for High-Flow, Low-Pressure Applications

Centrifugal pumps are widely used for moving large volumes of low-viscosity fluids in:

- Municipal water supply systems

- HVAC systems (air conditioners, water circulators)

- Irrigation and agricultural operations

- Petrochemical and fuel transfer stations

- Firefighting systems

- Cooling towers and boiler feeds

- Additional Capability: Centrifugal pumps with a vortex impeller can handle some solids in fluids, making them useful in wastewater applications.

Positive Displacement Pumps: Best for High-Pressure, Low-Flow Applications

Positive displacement pumps excel in industries where precise fluid control and pressure maintenance are required:

- Sewage and wastewater treatment plants

- Oil refineries and crude oil transport

- Food and beverage processing (e.g., syrups, dairy, sauces)

- Chemical manufacturing plants

- Pulp and paper industry (handling slurries and pastes)

Industry Example:

Food processing facilities often require both types of pumps:

- Centrifugal pumps move large quantities of water for cleaning and ingredient transport.

- Positive displacement pumps handle thick mixtures like dough, chocolate, or syrups at a controlled rate.

Making the Right Choice

When selecting a pump, consider the following criteria:

| Factor | Choose a Centrifugal Pump If… | Choose a Positive Displacement Pump If… |

| Fluid Type | You need to pump low-viscosity fluids (water, fuel, chemicals). | You need to pump thick, viscous, or shear-sensitive fluids. |

| Flow Requirements | You require continuous, high-volume flow with minimal pressure control. | You need precise flow control, even under varying pressures. |

| Startup Requirements | You can prime the pump before operation. | You need a dry-start capable pump. |

| System Complexity | You prefer a simpler system with lower maintenance. | You need precise flow control and can accommodate additional maintenance. |