In the demanding and rugged mining landscape, reliable supply is essential to maintain productivity and profits. Hydrophores, which are among the main tools used in mining, play an important role in supporting the transportation of various materials. To end the life of these pumps and improve their performance, miners need to use certain practices and strategies. In this blog, we’ll explore simple tips for extending the life of high-pressure pumps in mining, keeping them running smoothly and reducing downtime. In the fast-paced and complex world of mining, smooth operation of equipment is essential to maintain productivity and efficiency. profitability

Among the many types of equipment not used in mining, pressure pump concentrators stand out as important items that facilitate the transportation of various materials. Miners need to use certain practices and strategies to realize the full potential of these pumps. In this blog, we’ll dive into simple tips that can extend the life of high-pressure pumps in mining, ensure no downtime, and reduce downtime.

1. Pump selection:

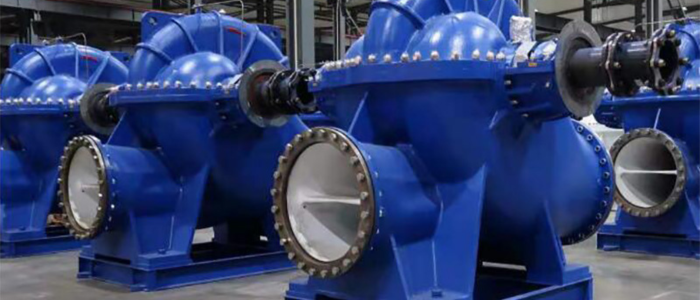

The foundation of the Long-Life Pressure Pump Booster begins with choosing the right pump for your mining operation. Consider factors such as flow, capacity, compatibility, and overall pump performance. A similar pump will have less stress during operation, reduce wear and extend its life.

2. Regular Maintenance Schedule:

Having a proper maintenance schedule is essential to maintain the efficiency and longevity of your High-pressure pump. Routine inspection, maintenance, and lubrication reduce the risk of clogging and damage by preventing build-up of deposits and bacteria. Create a maintenance log and keep a close eye on it so potential issues can be identified early and resolved in a timely manner.

3. Take care of your work:

The mining environment can be harsh; dust, temperature changes and humidity can be difficult for the life of the equipment. Install sensors and control systems to monitor operational parameters such as level, temperature and vibration. By paying close attention to these parameters, miners can identify critical errors and make corrections before they cause the pump to fail.

4. Pump properly:

It is important to store the pump properly when not in use. Make sure the pump is thoroughly cleaned before storing to remove any buildup or blockage. Also, store pumps in a dry and manageable location to protect them from corrosion and other environmental damage.

5. Employee education and knowledge:

Well-trained employees who understand that the tools they work on are essential to life. Regular training is available to train workers in proper use, maintenance procedures, and early signs of pump problems. Promoting a culture of knowledge and responsibility among employees will affect their quality of life.

6. Address cavitation and pressure fluctuations:

Cavitation and pressure fluctuations damage pump boosters. These problems can damage pumps, resulting in reduced performance and premature failure. Take steps such as installing surge protectors, ensuring proper pipe size, and proper maintenance to prevent cavitation and pressure surges.

7. Improved pump technology:

There are new pump models with higher efficiency and longer service life than Technology. Consider upgrading your old pump to a newer, more powerful model for better performance and longer life. In the long run, the initial investment will pay for itself through reduced maintenance costs and increased productivity.

In the harsh mining environment, high pressure boosters play an important role in managing operations. By choosing the right pump, following a regular work schedule, monitoring performance, miners can extend the life of their high-pressure pumps by keeping the pump in good condition and improving the user experience. In terms of cavitation and pressure changes and the use of pump technology to increase efficiency and reduce downtime. Thanks to these applications, business can only be efficient and reliable, increasing productivity and overall profit.