Fluid transportation industries face the issue of Cavitation in Pumps: Causes, Effects and Prevention, which can have a significant impact on pump performance and longevity. the concept of Cavitation is fundamental in pump systems, and it involves the understanding of cavitation and its influence on pumps to ensure that pumps operate at a high efficiency level.

The sudden collapse of vapor bubbles that are carried to higher pressure areas leads to the formation of shockwaves and high-pressure zones. the collapse and turbulence that ensued can have detrimental effects on pumps.

WHAT IS CAVITATION?

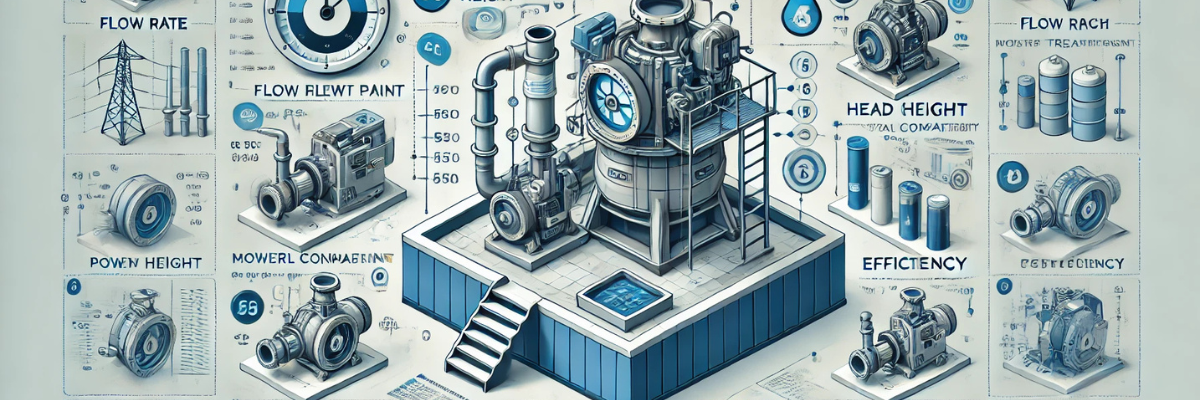

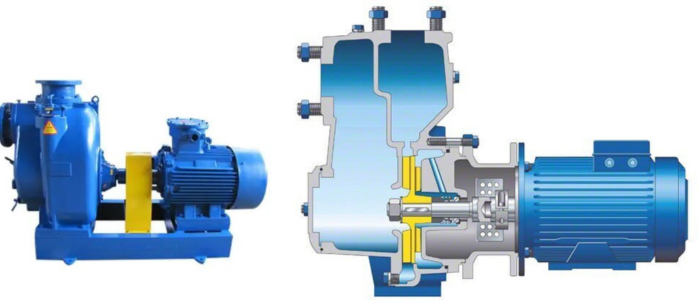

The displacement of vapor bubbles that reach higher areas of the fluid is caused by drops in a fluid’s corresponding evaporative pressure. rapid bubble collapse results in shockwaves and high-pressure zones, which can have detrimental effects on pumps. Initially, cavitation reduces pump efficiency. Vacuum bubbles interfere with the natural fluid flow, leading to a decrease in pump efficiency.

EFFECTS OF CAVITATION IN PUMPS:

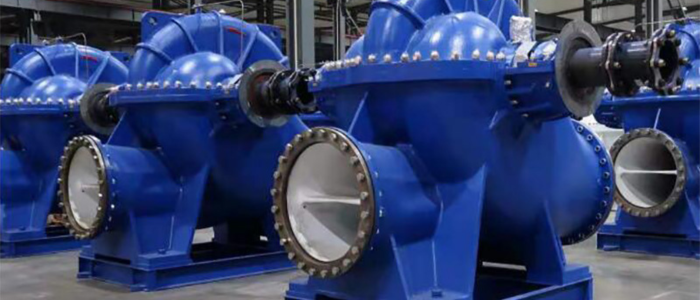

The pump’s lower flow rate and reduced head are a consequence of this, which limits its ability to transport fluids. the collapse of vapor bubbles during cavitation results in high-speed liquid jets that impact the pump’ surface. The pump’s lifespan is reduced due to the erosion and pitting that occur over time, which are caused by this continuous impact.

Noise and vibration are among the other effects of cavitation. the sudden collapse of vapor bubbles leads to excessive noise and mechanical stress on pump components, which in turn creates an uncomfortable work environment and accelerates wear and tear, necessitating frequent maintenance. additionally, cavitation causes pumps to have higher operating temperatures. Vapor bubbles collapse and generate heat, which causes the fluid surrounding them to become warmer. the deterioration of fluid lubricity can lead to increased pump friction and the potential for overheating of components.

CONCLUSION:

The likelihood of pumps failing due to cavitation is higher, necessitating frequent maintenance. the impact of cavitation on pumps is not only a concern for industrial processes but also has the potential to cause operational downtime and disruptions, including reduced efficiency, mechanical damage, noise, elevated temperatures, and compromised reliability. Industry dependent on pump systems must take preventive action and maintenance to mitigate the effects of cavitation so that their equipment can continue to function for extended periods. The prevention and mitigation of cavitation risks in pump systems is crucial for industries to achieve optimal efficiency, reduced downtime, and improved equipment reliability by ensuring the appropriate use of pumps, system design, consistent maintenance, etc.