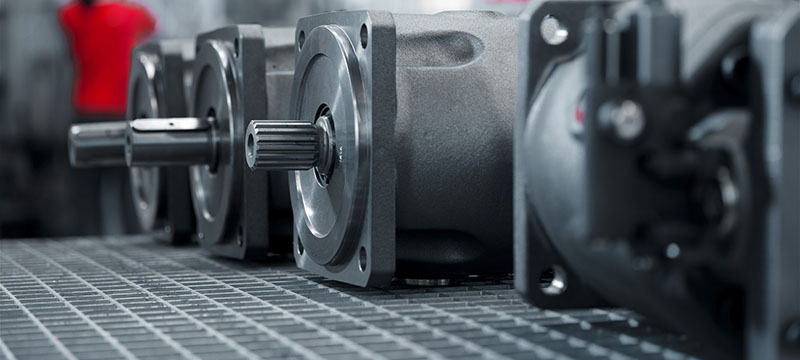

An industrial hydraulic pump is a device used to convert mechanical energy into hydraulic energy, typically by moving fluid (oil, water, or other liquids) through a system at high pressure. These pumps are critical in various industries to drive hydraulic systems, enabling machinery and equipment to perform tasks that require large amounts of force or precise control.

Types of Industrial Hydraulic Pumps:

- Gear Pumps:

- Working: Uses interlocking gears to transfer fluid and generate pressure.

- Advantages:

- Simple design and low cost.

- Reliable for low- to medium-pressure applications.

- Applications: Widely used in industrial machinery, construction equipment, and material handling systems.

- Piston Pumps:

- Working: Uses a piston moving back and forth within a cylinder to push fluid through the system.

- Advantages:

- Capable of generating very high pressure.

- Suitable for heavy-duty and high-performance applications.

- Applications: Used in heavy machinery, hydraulic presses, and aerospace industries.

- Vane Pumps:

- Working: Uses a rotor with extendable vanes that create chambers to move fluid through the pump.

- Advantages:

- High efficiency and low noise.

- Suitable for medium-pressure applications.

- Applications: Used in plastic injection molding machines, die-casting machines, and vehicle hydraulics.

- Radial Piston Pumps:

- Working: Has pistons arranged radially around a central drive shaft, providing powerful force as they push fluid outward.

- Advantages:

- Provides very high-pressure capabilities.

- Ideal for applications requiring consistent flow and precision.

- Applications: Used in mining, oil and gas industries, and high-pressure industrial machinery.

- Axial Piston Pumps:

- Working: Operates with pistons arranged in a parallel orientation to the drive shaft, creating flow and pressure by moving the pistons back and forth.

- Advantages:

- High efficiency and adjustable flow rates.

- Suitable for both high- and low-pressure applications.

- Applications: Found in construction equipment, hydraulic presses, and aircraft systems.

- Screw Pumps:

- Working: Utilizes two or more interlocking screws that rotate to move fluid through the pump.

- Advantages:

- Suitable for high-viscosity fluids.

- Quiet operation and low maintenance.

- Applications: Commonly used in marine hydraulics, oil and gas processing, and chemical plants.

- Bent Axis Pumps:

- Working: The pistons move at an angle relative to the pump shaft, creating a hydraulic force by pushing fluid through the system.

- Advantages:

- High-pressure capability with adjustable displacement.

- Compact and efficient design.

- Applications: Used in mobile hydraulic equipment, power steering systems, and industrial presses.

Key Applications of Industrial Hydraulic Pumps:

- Construction Equipment:

- Application: Hydraulic pumps power heavy machinery such as excavators, bulldozers, backhoes, cranes, and loaders. These machines use hydraulic pumps to generate the force required for lifting, digging, and moving heavy materials.

- Benefits:

- Provides precise control over powerful equipment.

- Enables heavy-duty tasks with minimal manual labor.

- Manufacturing and Automation:

- Application: Hydraulic systems are essential in various manufacturing processes, including plastic injection molding, metal stamping, die-casting, and press operations. Hydraulic pumps provide the necessary pressure to power actuators and presses.

- Benefits:

- Ensures precise, repeatable operations in automated production lines.

- Supports high-pressure forming and molding processes.

- Hydraulic Presses:

- Application: Hydraulic presses use hydraulic pumps to generate the enormous force needed for compressing, molding, or shaping materials. This is commonly used in the automotive, metalworking, and plastics industries.

- Benefits:

- Provides reliable, consistent pressure for shaping materials.

- Capable of generating significant force for industrial tasks.

- Agriculture and Forestry Equipment:

- Application: Hydraulic pumps are found in tractors, harvesters, log splitters, and other agricultural machinery. These systems are used to control plows, harvesters, and other attachments, improving efficiency in farming and forestry operations.

- Benefits:

- Enhances the efficiency of agricultural operations by providing hydraulic power to various tools.

- Simplifies lifting, digging, and moving large loads.

- Marine and Offshore Industry:

- Application: Hydraulic pumps are used in marine equipment, including winches, steering systems, and cranes on ships and oil rigs. They are essential for underwater operations, such as subsea drilling and remote-operated vehicles (ROVs).

- Benefits:

- Provides precise control and power for marine applications.

- Operates reliably in harsh, corrosive environments.

- Aerospace and Aviation:

- Application: Hydraulic pumps are critical in aircraft systems, powering landing gear, brakes, flaps, and flight controls. These pumps provide the high-pressure hydraulic fluid needed to control various aircraft functions.

- Benefits:

- Offers reliable and precise control in flight-critical systems.

- Supports high-pressure applications required for aircraft operations.

- Oil and Gas Industry:

- Application: Hydraulic pumps are used for various operations, including drilling, hydraulic fracturing (fracking), and wellhead control. They power hydraulic tools and systems in the exploration, extraction, and processing of oil and natural gas.

- Benefits:

- Provides the high-pressure capability required for drilling and extraction.

- Operates reliably in extreme conditions.

- Mining Operations:

- Application: Hydraulic pumps power drilling rigs, rock crushers, and conveyor belts in mining operations. They are used to move heavy loads, operate mining machinery, and control hydraulic systems in underground or open-pit mining.

- Benefits:

- Provides power to equipment for breaking, drilling, and material handling.

- Capable of handling tough, abrasive conditions.

- Power Generation:

- Application: In hydroelectric power plants and other energy generation facilities, hydraulic pumps are used to control turbines and other hydraulic systems for energy production and distribution.

- Benefits:

- Supports the operation of large-scale turbines and generators.

- Provides reliable, continuous power for energy systems.

- Transportation:

- Application: Hydraulic pumps are used in heavy vehicles such as trucks, buses, and trains for power steering, braking systems, and hydraulic lifts. They provide power to various systems that enable smooth operation and control.

- Benefits:

- Improves control and maneuverability in large vehicles.

- Enhances safety through hydraulic braking systems.

- Defense and Military:

- Application: Hydraulic pumps are used in military vehicles, aircraft, and weaponry to operate steering, lifting, and combat systems. They provide the necessary force for mission-critical operations such as tank controls and weapons deployment.

- Benefits:

- Provides reliable power and control for critical military equipment.

- Ensures high-pressure operation in harsh environments.

- Recycling and Waste Management:

- Application: Hydraulic pumps are used in recycling plants and waste management facilities to operate balers, compactors, and shredders. These machines compress, shred, and handle recyclable materials.

- Benefits:

- Enhances the efficiency of waste processing and material handling.

- Provides the high-pressure capability required for compacting waste materials.

Key Considerations for Selecting an Industrial Hydraulic Pump:

- Pressure Requirements: Choose a pump that can meet the necessary operating pressure for the application.

- Flow Rate: The pump’s flow rate must be sufficient to meet the operational demands of the hydraulic system.

- Fluid Type: Ensure the pump is compatible with the hydraulic fluid used in the system, whether it’s oil, water, or other fluids.

- Efficiency: High-efficiency pumps can reduce energy consumption and operating costs, especially in large-scale industrial operations.

- Operating Environment: Consider the operating conditions (temperature, humidity, exposure to chemicals) to ensure the pump materials and design can withstand the environment.

- Maintenance and Durability: Choose pumps with a good track record for durability and low maintenance, especially for critical applications where downtime can be costly.

Industrial hydraulic pumps are the backbone of countless applications across industries, providing the power and precision needed for heavy-duty tasks and automated processes.