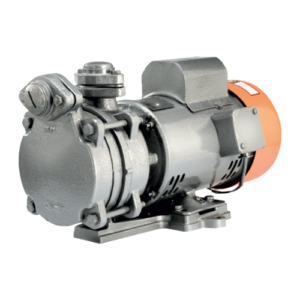

Ebara Pumps Model GSD

Direct coupled single-stage end suction pump

Features and Benefits

Energy-saving design

・World top class pump efficiency achieved. (MEI>0.6)

・Major improvement over our previous models by impeller designed using our proprietary 3D inverse design technology.

・Higher efficiency means lower energy consumption and motor output, and more compact size.

・Adjustable for outer diameter of Impeller

Simple Maintenance

・Back pull-out structure enables disassembly and inspection without removal of suction and discharge piping.

・Shield bearings eliminate need for adding or exchanging lubricating oil.

・Shaft seal flushing and quenching piping not required for the standard application.

・Air-bleeding not required.

・Simplified bearings and shaft seal enable easy assembly.

Pump specifications

・Compatible with multiple flange standards.

・Able to meet customer specifications with many combinations of shaft seals and materials.

・Complies with CE marking and RoHS directive.

・Protector fitted in accordance with ISO13852

Description :

Specifications

| Capacities | To 700 m3/h (50Hz) | |

| Heads | To 150 m | |

| Liquid temperatures | -10℃ to 120℃ | |

| Max. working pressures | 1.6MPa | |

| Standard allowable boost pressure | 1.6 – “Shut-off pressure” MPa | |

| Construction | Impeller | Closed, single suction type and balancing holes to reduce axial thrust |

| Shaft seal | Single mechanical seal based upon EN12756 (Conical type) | |

| Pump Bearing | ― | |

| Materials | Casing | Cast Iron (FC250) |

| Impeller | Cast iron (100/125/150-400: FCD400, other models: FC200) | |

| Bronze (CAC406) | ||

| Shaft | SUS420J2Q (Wetted part) | |

| Applicable pump standard | EN733 | |

| Applicable flange standard | EN PN16 | |