Flowserve Pumps API Process Pumps – ERPN

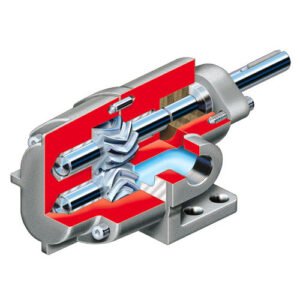

The ERPN is the pump of choice for severe chemical, petrochemical, refining and heavy-duty industrial service where deviations to API 610 are accepted. This pump provides users with the important mechanical, hydraulic, emissions control and safety components required by the latest ISO 13709/API 610 standards.

Description :

Industries

- General Industry

- Chemicals

- Water

- Oil & Gas

- Power

Industry Sectors

- Pulp & Paper

- Other Industries

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Water

- Upstream Exploration & Production

- Downstream Processing

- Conventional Steam

- Combined Cycle

Standards

- Flowserve

- Hydraulic Institute

- ISO 13709 / API 610 (with deviation)

- ISO 21049 / API 682 seal chamber and seal flush plans

Operating Parameters

- Flows to 1100 m3/h (4800 gpm)

- Heads to 230 m (750 ft)

- Pressures to 60 bar (870 psi)

- Temperatures -50°C (-58°F) to 350°C (660°F)

Features and Benefits

- Single stage, radially split, overhung, centerline mounted pump, designed in accordance to ISO13709 / API 610 latest edition OH2 requirements, only deviating from this standard by using a rear pump bearing housing support

- Available in a wide range of materials like S5, S6, C6, A8, D1, D2 and LTS material, special alloys, titanium, NACE MR0175 and MR0103 compliant materials

- Back pull-out design for ease of maintenance, less wear parts

- Closed, semi-open or open impeller are available as well inducers for low NPSHa applications

- The self venting casing has a top discharge, double or single volute depending on size and can be equipped with a steam heating jacked

- Anti vortex plates grant optimized suction behavior