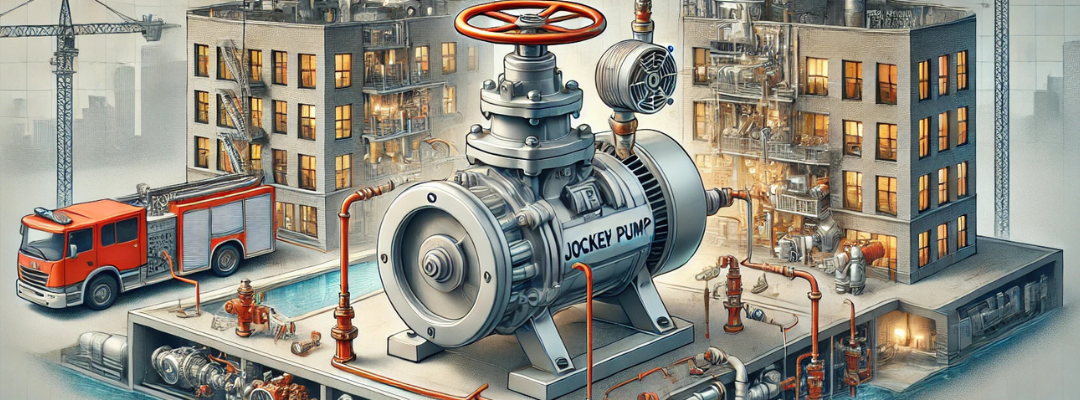

Properties and Importance of a Jockey Pump

A jockey pump is a small, auxiliary pump that is part of a fire protection system, designed to maintain pressure in the system’s piping network and prevent unnecessary operation of the main fire pump. Jockey pumps play a critical role in ensuring that the fire protection system remains primed and ready to deliver water in case of an emergency, without frequent cycling of the main fire pump.

Key Properties of a Jockey Pump:

- Pressure Maintenance

- The primary function of a jockey pump is to maintain pressure in the fire sprinkler system or fire suppression piping network. It compensates for small pressure drops due to minor leaks, system testing, or thermal expansion without engaging the main fire pump.

- The jockey pump operates within a set pressure range, usually maintaining the system pressure just below the cut-in pressure of the main fire pump. It automatically activates when the pressure drops slightly and turns off when the pressure is restored to the desired level.

- Low Flow Rate

- Flow rate is typically low, since jockey pumps are designed to compensate for minor leaks or pressure drops, not to provide water for firefighting. The flow rate is usually measured in gallons per minute (GPM) or liters per minute (LPM) and is much lower than that of the main fire pump.

- Typical flow rates for jockey pumps range from 10 to 50 GPM (or 40 to 190 LPM), depending on the size of the fire protection system.

- Material Construction

- Jockey pumps are made from durable, corrosion-resistant materials such as stainless steel, bronze, or cast iron, ensuring longevity and reliability, especially when exposed to water and other environmental factors.

- The wetted parts of the jockey pump must be able to withstand corrosive environments and treated water used in fire protection systems.

- Automatic Operation

- Jockey pumps are equipped with pressure sensors or pressure switches to detect drops in system pressure. When a drop in pressure is detected, the jockey pump automatically activates to restore the pressure, then shuts off once the desired pressure level is achieved.

- The system’s automation ensures that the fire suppression system remains pressurized and ready without requiring manual intervention.

- Energy Efficiency

- Since jockey pumps run intermittently and handle low flow rates, they are designed to be energy-efficient, using minimal power to maintain the system pressure. The motor size is typically small, with power ratings ranging from 0.5 HP to 10 HP (0.37 kW to 7.5 kW), depending on system requirements.

- Centrifugal Design

- Centrifugal pumps are commonly used as jockey pumps due to their efficiency in maintaining pressure in low-flow conditions. These pumps are ideal for providing consistent and reliable pressure without significant energy consumption.

- Pressure Range Settings

- Jockey pumps are designed to operate within a specific pressure range. The cut-in pressure (the pressure at which the jockey pump starts) and the cut-out pressure (the pressure at which the jockey pump stops) are adjustable, depending on the needs of the fire protection system.

- The jockey pump typically starts when the system pressure drops 10-20 psi below the operating pressure and stops once the pressure is restored to the desired level.

- Compact Size

- Jockey pumps are compact in size, allowing for easy installation within the overall fire protection system. Their small footprint makes them ideal for installations in confined spaces such as mechanical rooms, basements, or within the fire pump room.

- Low Maintenance

- Jockey pumps are designed for low maintenance and reliable operation. Since they operate intermittently and handle low-flow conditions, they experience less wear and tear compared to the main fire pump. Routine checks are often sufficient to ensure their operational readiness.

Importance of a Jockey Pump:

- Pressure Maintenance in Fire Protection Systems

- The jockey pump’s main function is to maintain constant pressure in the fire protection system. By compensating for minor drops in pressure caused by small leaks, system tests, or fluctuations, the jockey pump ensures that the system is always ready to activate in case of an emergency.

- This prevents pressure drops that could compromise the readiness of the system and ensures that when the fire suppression system activates, water is immediately available at the required pressure.

- Prevents Frequent Cycling of the Main Fire Pump

- Without a jockey pump, any small drop in system pressure would trigger the main fire pump, which is designed for high-flow firefighting scenarios. Frequent starting and stopping of the main pump due to minor pressure changes would cause excessive wear and tear, increasing maintenance costs and reducing the pump’s lifespan.

- The jockey pump minimizes unnecessary cycling of the main fire pump, allowing the main pump to operate only during actual firefighting situations.

- Ensures Fire System Readiness

- The jockey pump helps to keep the fire protection system fully pressurized at all times, ensuring that the sprinklers or hydrants are ready to operate when needed. If a fire emergency occurs, the main fire pump can activate immediately, providing full flow and pressure for firefighting.

- In essence, the jockey pump acts as the “guardian” of the system, ensuring that the fire pump only operates when a significant pressure drop occurs (e.g., due to sprinkler activation or fire hose use).

- Reduces Wear and Tear on the Fire Pump

- By maintaining system pressure and reducing the need for the main fire pump to activate unnecessarily, the jockey pump significantly reduces wear and tear on the main fire pump and related components.

- This leads to lower maintenance costs and extends the operational life of the fire pump, contributing to the overall longevity and reliability of the fire protection system.

- Energy Efficiency and Cost Savings

- Jockey pumps are typically smaller and consume much less energy than the main fire pump. By using the jockey pump to maintain pressure, facilities can achieve energy savings, as the high-power fire pump is only activated during fire emergencies.

- This makes the system more efficient and cost-effective, especially in facilities where minor leaks or pressure drops are common, such as large commercial or industrial buildings.

- Automatic Operation and System Integrity

- The jockey pump’s automatic pressure control ensures that system integrity is maintained without manual intervention. The automatic start and stop of the jockey pump mean that even minor pressure drops are corrected immediately, maintaining the system’s readiness at all times.

- This automation reduces the need for constant human oversight, making the system more reliable and ensuring consistent performance.

- Critical Role in Safety Compliance

- Jockey pumps are an essential part of fire protection systems in buildings that require compliance with fire safety codes and insurance requirements. By maintaining the correct pressure in the fire suppression system, the jockey pump ensures that the system meets safety standards and performs as expected in an emergency.

- In many jurisdictions, fire protection systems must be equipped with jockey pumps to meet regulatory standards, especially in commercial, industrial, and high-rise buildings.

- Reduces Downtime and Improves Reliability

- By preventing unnecessary operation of the main fire pump, the jockey pump reduces the chances of system failures and downtime due to maintenance or repairs. The improved reliability of the fire protection system means that it is always available to respond to emergencies.

- Facilities that rely on fire protection systems benefit from the peace of mind that the jockey pump provides, knowing that the system is continuously pressurized and ready for use.

Conclusion:

The jockey pump is a vital component of a fire protection system, ensuring that the system remains pressurized and ready to deliver water in the event of a fire. By maintaining pressure and preventing the main fire pump from cycling unnecessarily, the jockey pump reduces wear and tear, improves energy efficiency, and enhances the overall reliability of the fire suppression system. It plays a crucial role in ensuring that fire safety systems meet regulatory requirements and are always ready to protect lives and property during emergencies.