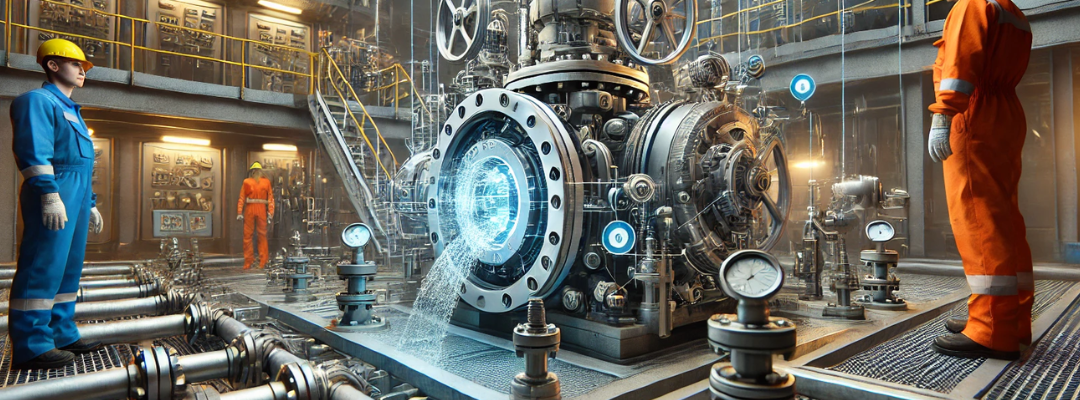

A pump diverter valve is a specialized valve used to control the flow of fluid in pump systems. It is designed to divert the flow from one direction or outlet to another, allowing fluid to be directed to different parts of the system or to isolate specific parts of the system during maintenance or operational adjustments. Diverter valves are commonly used in industries like oil and gas, chemical processing, water treatment, and manufacturing.

Key Functions:

- Flow Control: A pump diverter valve directs the flow of liquid to different outlets or branches in a system. This helps in distributing fluids to the desired locations without the need for stopping the pump.

- System Isolation: It can isolate certain parts of the system during maintenance or repair work, making it easier to work on the system without shutting down the entire operation.

- Pressure Regulation: In some systems, a diverter valve is used to manage and regulate pressure by diverting excess fluid away from sensitive parts of the system.

Common Applications:

- Water Treatment: Pump diverter valves are used to direct water through various stages of treatment or filtration processes.

- Oil and Gas: In oil production, diverter valves help manage flow between different pipelines or treatment units.

- Chemical Processing: Used in systems where different processes need to be fed from a common pump, allowing redirection of chemicals as needed.

- HVAC Systems: In heating and cooling applications, they help divert water or refrigerants through different circuits for temperature control.

- Irrigation Systems: They allow redirection of water from pumps to various zones or areas in large-scale agricultural systems.

In summary, a pump diverter valve provides flexibility, control, and safety in various pump-driven systems by allowing operators to manage fluid flow more effectively.