PUMPS FOR FOOD INDUSTRIAL PROCESS

Experience the Future of Food Processing Pumps. From Gentle Handling of Delicate Ingredients to High-Volume Production, We Optimize Efficiency, Quality, and Safety for all your food procesing needs.

Pumpscart is a prominent supplier and exporter of Food Industry Pumps in India. Pumscart Food Grade Pumps, all metallic parts in contact with the media being handled are fabricated in smooth finish stainless steel. These pumps are provided with metal-bonded aseptic food-grade elastomeric stators resistant to oil & fats. Pumpscart Pumps are designed to maintain absolute hygiene and are among the easiest to clean and maintain. From the thickest pastes to highly viscous liquids and shear-sensitive media’s pumping solutions for the food and beverages industry are not only required to handle various applications but are also expected to maintain the highest standards of hygiene and safety.

Types of Food Industry Pumps

Positive Displacement Pumps

Positive displacement pumps, particularly progressive cavity pumps, are used for pumping food products with varying viscosities. They provide a consistent and gentle flow, making them suitable for applications like transferring sauces, creams, and fillings.

Common Applications: Ideal for transferring sauces, creams, fillings, and other high-viscosity food products.

General Specs: Progressive cavity design for consistent and gentle flow, hygienic materials, and easy maintenance.

Food Dosing pumps

Dosing pumps are small positive displacement pumps, designed to offer a precise flow rate by drawing a specific amount of liquid into a chamber to be injected substance. They are usually powered by an electric motor or air actuator, and controlled by an external control system or an internal pump controller, which allows for minimal loss. Dosing pumps can handle a range of fragile fluids with solids (up to 48 mm) which makes them suitable for use over a number of industries.

Food Peristaltic pumps

Peristaltic pumps are ideal for the food industry due to their hygienic and gentle pumping action. They use a flexible tube to create a rolling motion, preventing contamination and ensuring the integrity of sensitive food products.

Common Applications: Used for precise dosing, transferring liquids, and handling shear-sensitive and delicate food products. Ideal for the dairy and beverage industry.

General Specs: Typically constructed with food-grade materials, easy to clean, and designed for accurate and gentle fluid handling

Diaphragm Pumps

Positive displacement pumps, particularly progressive cavity pumps, are used for pumping food products with varying viscosities. They provide a consistent and gentle flow, making them suitable for applications like transferring sauces, creams, and fillings.

Common Applications: Ideal for transferring sauces, creams, fillings, and other high-viscosity food products.

General Specs: Progressive cavity design for consistent and gentle flow, hygienic materials, and easy maintenance.

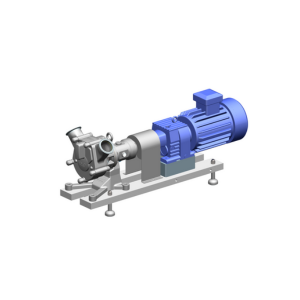

Centrifugal Pumps with Sanitary Design

Centrifugal pumps with sanitary design features are specifically crafted for the food industry. They are easy to clean, resistant to corrosion, and comply with hygiene standards, making them suitable for handling various food products.

Common Applications: Used for fluid transfer, product recirculation, and CIP (Clean-In-Place) processes in the food industry.

General Specs: Sanitary design with polished surfaces, easy disassembly for cleaning, and compliance with food safety and hygiene standards.

Air-Operated Double Diaphragm (AODD) Pumps

AODD pumps are versatile and easy to clean, making them suitable for the food processing industry. They are often used for pumping various food-grade liquids, including beverages and sauces.

Common Applications: Versatile pumps suitable for handling a wide range of food-grade liquids, including beverages, sauces, and food additives.

General Specs: Simple and reliable design, sealless operation, easy cleaning, and flexibility for various food processing tasks.

Gear Pumps with Sanitary Design

Gear pumps with a sanitary design are commonly employed in the food industry for transferring liquids with a smooth and consistent flow. These pumps are easy to disassemble and clean, meeting the stringent hygiene standards.

Common Applications: Used for smooth and consistent transfer of liquids, such as chocolate, syrups, and oils, while maintaining product quality.

General Specs: Sanitary design, precision engineering, and ease of cleaning to meet strict food industry standards.

Hygienic Lobe Pumps

Lobe pumps designed with hygiene in mind are used in the food processing industry for the gentle handling of delicate food products. They are particularly suitable for transferring viscous materials without compromising product quality.

Common Applications: Gentle handling of viscous food products, such as yogurt, cream, and fruit fillings, to preserve product quality.

General Specs: Hygienic design, low shear, and materials compatible with food processing.

Circumferential Piston (CP) Pumps

CP pumps are designed for the hygienic transfer of food products, especially those with suspended solids. They offer a smooth and controlled flow, making them suitable for applications like fruit and vegetable processing.

Common Applications: Designed for fruit and vegetable processing, handling pulpy and solids-laden food products.

General Specs: Hygienic construction, precise and controlled flow, and compliance with food safety requirements.

Sine Pumps

Sine pumps, also known as sinusoidal pumps, are employed for handling shear-sensitive food products. They provide a gentle pumping action, making them suitable for applications in the dairy and beverage industries.

Common Applications: Used for shear-sensitive food products, ensuring gentle handling of dairy and beverage ingredients.

General Specs: Sine-wave motion for gentle product transfer, food-grade materials, and ease of cleaning.

Twin Screw Pumps

Twin screw pumps are used for transferring high-viscosity food products, such as pastes and creams. They provide a reliable and consistent flow while maintaining the quality of the food being processed.

Common Applications: Ideal for transferring pastes and creams, such as peanut butter and chocolate, while maintaining product consistency.

General Specs: Twin-screw design, hygienic materials, and reliable performance for high-viscosity foods.

Applications of Pumps in the Food Processing Industry:

1. Transfer of Food Products: Pumps are used to transfer various food products, such as liquids (milk, juice, sauces), purees, and viscous materials (chocolate, dough), between processing stages or from storage to production lines.

2. Dosing and Mixing: Pumps accurately dose ingredients like flavorings, colors, and additives into food products. They also facilitate the blending of multiple components to ensure product uniformity.

3. Hygienic Filling: In beverage and dairy industries, pumps fill containers, such as bottles and cartons, with precision, maintaining hygiene and reducing product wastage.

4. Pumping Shear-Sensitive Products: For products like yogurt, custards, and creams, pumps with low shear action are employed to prevent texture and quality alterations.

5. CIP (Clean-In-Place) Processes: Pumps assist in the circulation of cleaning solutions and hot water during sanitation procedures, ensuring the highest hygiene standards.

6. Handling Solids and Particulates: Certain foods contain solids, such as soups with vegetables or sauces with particulates. Pumps designed for solids transfer are used for gentle handling.

Technological Advancements and Innovations:

1. Enhanced Hygienic Design: Pumps designed for the food industry feature polished surfaces, crevice-free construction, and easy disassembly for a thorough cleaning, reducing the risk of contamination.

2. Smart Pumping Systems: Integration of sensors and automation allows precise control, real-time monitoring, and predictive maintenance, ensuring efficiency and product consistency.

3. Sealless Pump Technologies: Innovations in sealless pump designs, including magnetic drives, reduce the risk of leaks and enhance safety in food processing.

4. Energy Efficiency: Energy-efficient pump designs and variable frequency drives (VFDs) help reduce energy consumption and operational costs in food processing facilities.

5. Remote Monitoring and Control: IoT (Internet of Things) and remote monitoring systems provide real-time access to pump performance data, allowing for efficient management and maintenance.

Challenges and Solutions:

1. Hygiene and Contamination: The food industry’s primary challenge is maintaining strict hygiene standards. The solution is using pumps with hygienic designs, clean-in-place (CIP) procedures, and stringent cleaning protocols.

2. Viscous and Shear-Sensitive Products: Handling products with varying viscosities or shear sensitivity requires specialized pumps with gentle handling mechanisms, such as peristaltic or lobe pumps.

3. Solids and Particulates: Pumps need to handle products with suspended solids or particulates effectively. The solution is choosing pumps designed for solids transfer and maintaining their cleanability.

4. Changing Consumer Preferences: Food trends evolve, and manufacturers must adapt quickly. Flexible pumping systems and versatile pump designs help address these changes efficiently.

5. Energy Consumption: Reducing energy consumption is a growing concern. Employing energy-efficient pump designs and optimizing pump operation with VFDs can address this challenge.

6. Product Quality and Consistency: Maintaining product quality and consistency throughout the production process is vital. Precise dosing, blending, and monitoring with smart pumping systems are key solutions.

FAQ

What is a food grade pump?

Food Grade Pumps aren’t limited to just the food industry. These high-quality pumps are designed to adhere to strict hygienic standards for use in the Pharmaceutical, Food, Beverage, and Cosmetics industries.

What is pump in food?

Food pumps are used throughout the food and beverage industries to transfer, mix and dose fluid and semi-fluid substances in processing and production applications. Pumps for food processing are manufactured from food grade materials and have smooth surfaces to prevent contamination from food and bacteria buildup.

Uses of food pumps

Petfood processing equipment.

Dairy pumps & processing equipment.

Beverages: PCM pumps & equipment.

Convenience food: Dosing and filling PCM pumps & equipment.

Fruits and vegetables: PCM pumps & equipment. Sugar and starch market: PCM pumps & equipment.

Meat and fish pumps.

Features that pumps must have for food and beverage applications

Handling a broad temperature range.

Managing routine cleaning/sanitization.

Ensuring hygiene and protection from contamination.

Accomplishing loading, unloading and transferring functions.

Food Pumps Specifications

Capacity Up to 50 m³/hr.

Pressure Stages 6, 12, 18 & 24 Bar

Temperature Up to 150° C / 302° F

Viscosity Up to 30,000 cst

Solid Handling Capability Up to 12%

What types of pumps are commonly used in the food processing industry?

Commonly used pumps in the food processing industry include centrifugal pumps, positive displacement pumps (progressive cavity, diaphragm), lobe pumps, peristaltic pumps, and gear pumps, among others.

How do I choose the right pump for my food processing application?

Selecting the right pump depends on factors such as the type of food product, viscosity, flow rate, and the need for hygienic handling. Consult with pump experts to ensure the pump’s compatibility with your specific application.

What are the hygienic standards for pumps in food processing, and how are they maintained?

Hygienic standards include smooth, crevice-free surfaces, easy disassembly for cleaning, and compliance with food safety regulations. Maintenance involves regular cleaning, sterilization, and adherence to CIP (Clean-In-Place) procedures.

How are pumps cleaned and sanitized in the food industry?

Cleaning and sanitizing food pumps typically involve CIP processes, which use a combination of cleaning agents, hot water, and pumping actions to remove residue and eliminate pathogens.

Can pumps in the food industry handle shear-sensitive products without compromising quality?

Yes, certain pump types, such as peristaltic and lobe pumps, are designed to handle shear-sensitive products gently, preserving the texture and quality of food items.

What are the benefits of sealless pump technologies in food processing?

Sealless pump technologies, like magnetic drives, reduce the risk of leaks and contamination, making them ideal for handling food products and ensuring product purity.

How do pumps contribute to energy efficiency in food processing facilities?

Pumps with energy-efficient designs and the use of variable frequency drives (VFDs) help reduce energy consumption, ultimately cutting operational costs and aligning with sustainability goals.

Are there innovations in pump technology relevant to the food industry?

Yes, innovations include smart pumping systems with sensors and automation, remote monitoring and control, and advancements in hygienic design to enhance food safety and efficiency.

What are the challenges in handling products with solids or particulates in food processing, and how are they addressed?

Challenges include ensuring the even distribution of solids. Choosing pumps designed for solids transfer and maintaining their cleanability helps address these issues.

How can food manufacturers adapt to changing consumer preferences and trends with their pump systems?

Flexible pumping systems that allow for quick adjustments in product recipes and formulations help manufacturers adapt to changing consumer preferences efficiently.