Pumpscart – Your Mining Pump Partner

Unleash Mining Efficiency with Pumpscart! Discover a Wide Range of Pumps for Every Mining Application Reliable. Efficient. Cost-effective. Your Mining Success Starts Here!

Explore Pumpscart’s extensive range of pumps tailored for mining applications. From dewatering and slurry transport to tailings management, we offer reliable solutions to keep your mining operations efficient and eco-friendly. Enhance your mining success with Pumpscart’s expertly designed-pumps.

Types of Pumps Used in Mining

Slurry Pump

In the mining sector, the efficient transport of abrasive and corrosive slurries is a necessity. Pumpscart’s specialized slurry pumps are designed to meet this challenge head-on, extending pump lifespan and reducing maintenance costs.

Gravel Pump

Sand pump is most commonly used in the pumping system that move sand deposits to long distance. It is simply classified as sand pump, slurry pump and gravel pump. They are widely used in mining, metallurgy, coal washing, power plants, sewage water treatment, dredging, and chemical and petroleum industries.

Dredge Pump

Dredge pumps are a special category of heavy-duty slurry pumps that are utilized in the process of dredging. Dredging takes place in shallow water areas of lakes, rivers or ocean for the purpose of land reclamation, desilting, flood prevention. Hence, various industries which utilize dredge pumps are construction industry, mining industry, coal industry and oil & gas industry.

Submersible Pump

Pumpscart’s submersible pumps are engineered to work efficiently in challenging conditions. These pumps are the go-to choice for underwater applications, ensuring reliability and performance when submerged.

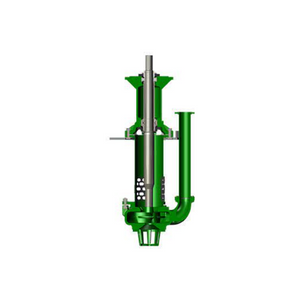

Vertical Slurry Pump

Vertical centrifugal pumps are also called as cantilever pumps. These pumps use an exclusive shaft & maintain design that permits the volume to fall within the pit as the bearings are external to the pit. This mode of pump utilizes no filling container to cover the shaft however in its place uses a throttle bushing.

Horizontal Pump

These pumps are utilized in pumping services. Every stage is fundamentally a divide pump. All the phases are in a similar shelter & mounted on a similar shaft. On a solo horizontal shaft, a minimum of eight otherwise additional stages can be mounted. Multi-stage pumps can also be single otherwise double suction on the first impeller.

Centrifugal Pumps

Pumpscart Pumps offers a range of centrifugal pumps designed to efficiently move large volumes of water, slurry, and other liquids. With robust construction and precise engineering, these pumps are ideal for tasks such as mine dewatering and mineral transport.

Positive Displacement Pumps

Our positive displacement pumps are tailored to handle high-viscosity fluids and are perfect for precise dosing and pressure control in mining processes.

Specialized Pumps

Our range also includes high-pressure pumps for underground mining, dewatering pumps for addressing flooding issues, and tailings pumps for responsible waste management.

Applications of Pumps in the Mining Industry

1. Mine Dewatering

With Pumpscart’s dewatering pumps, mining operations can remove excess water from pits and tunnels efficiently. This process ensures a safe and dry working environment, preventing delays and potential disasters.

2. Slurry Transport

Our slurry pumps are designed to handle the demanding task of transporting mineral-laden slurries. They minimize downtime, reduce energy consumption, and extend the life of essential components.

3. Tailings Management

Pumpscart Pumps offers specialized solutions for handling and disposing of mining waste, ensuring responsible and sustainable tailings management.

4. Water Supply and Treatment

We assist mining operations in procuring and treating water, offering reliable and efficient pump solutions to keep vital processes running smoothly.

5. Ventilation and Dust Control

Pumpscart’s pumps play a crucial role in maintaining air quality and safety within mines. By efficiently controlling dust and ensuring proper ventilation, we help protect the health and well-being of miners.

Technological Advancements and Innovations

1. Smart Pumping Systems

Pumpscart Pumps integrates cutting-edge sensors and automation to provide real-time monitoring and control, increasing the efficiency and reliability of mining operations.

2. Material and Design Improvements

Our commitment to innovation extends to wear-resistant materials and improved pump designs, ensuring our pumps perform optimally even in the harshest mining environments.

3. Energy Efficiency and Sustainability

Pumpscart Pumps prioritizes sustainability by offering energy-efficient technologies and environmentally responsible pump options, aligning with stringent environmental regulations.

Challenges and Solutions

1. Abrasion and Wear

We understand the wear and tear that mining pumps endure. Pumpscart Pumps offers solutions to mitigate wear and extend the life of our pumps, reducing operational costs.

2. Maintenance and Reliability

Pumpscart Pumps recognizes the importance of regular maintenance. We implement predictive maintenance strategies to ensure the reliability of our pumps, reducing downtime and associated costs.

3. Environmental Regulations

As a responsible industry player, Pumpscart Pumps remains committed to environmental compliance. Our innovative solutions aim to reduce the environmental impact of mining operations.

In conclusion, Pumpscart Pumps is at the forefront of advancing mining pump technology. We are committed to delivering reliable, efficient, and sustainable solutions, playing a vital role in the evolution of the mining industry. Our dedication to innovation and excellence remains unwavering, ensuring that mining operations around the world can continue to thrive.

FAQ

Mining pumps means?

Ore Mining Pumps are the types of mining pumps which in the ore mining process. Mining pumps work for mineral processing, slurry transfer, abrasive sludge dewatering, acid and chemical reagent dosing, water supply and boosting, and wastewater and tailing transfer.

What are the types of pumps?

Types of Pumps.

Centrifugal Pumps.

Vertical Centrifugal Pumps.

Horizontal Centrifugal Pumps.

Submersible Pumps.

Fire Hydrant Systems.

Diaphragm Pumps.

Gear Pumps.

How are pumps used in mining?

The mine water is pumped to a sump to be captured, then pumped to the surface with large multistage electric centrifugal pumps or other high-flow/high-pressure rotating pump technology. This process keeps the working area free from deep water and helps with miner safety, protects equipment and improves productivity.

Specialized Pumps for the Mining Industry?

From discovery to excavation, metal and mineral processing, and beneficiation, the mining industry involves a series of complex and intensive steps that could prove almost impossible without sturdy and effective mining pumps. Understanding this need Pumpscart designs efficient and reliable mining pumps, which are used in several applications in the mining industry.

Pumps Mining Specifications:

Max Flow Rate Upto 450 m3/hr

Motor Phase Single Phase

Applications Pipeline Pumping, Jetting Construction, Environmental, Industrial Clear Water

Voltage 230/415 V

Speed 1450/2900 RPM