Waste Water Treatment Pumps in India

Elevate Water Treatment with Pumpscart’s Precision Pumps. Our Expertly Engineered Solutions Ensure Efficient and Reliable Water Purification. Trust in Pumpscart for Your Water Treatment Needs and Experience Unparalleled Quality and Performance.

Pumpscart offers a comprehensive range of high-performance pumps designed to meet the exacting demands of water treatment. Our precision-engineered solutions ensure efficient and reliable water purification, covering a wide spectrum of applications. With Pumpscart, you can trust in our expertise to deliver the highest quality and performance in water treatment pumps, contributing to cleaner, safer water for communities and industries.

Types of Waste Water Treatment Pumps

Centrifugal Pumps

Centrifugal pumps are versatile and widely used in wastewater treatment for lifting, transferring, and circulating water and wastewater. They work by using centrifugal force to move fluids.

Common Specs:

| Feature | Specification |

| Flow Rates |

Varied based on pump size

|

| Solids Handling |

Limited (may require screening)

|

| Materials |

Cast iron, stainless steel, etc.

|

| Efficiency | Moderate to high |

| Priming | Requires priming |

Positive Displacement Pumps

Progressive cavity pumps are used for thick sludge and high-viscosity wastewater handling, providing a consistent and gentle flow.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for thick sludge

|

| Solids Handling | Excellent |

| Materials |

Stainless steel, abrasion-resistant materials

|

| Efficiency | Moderate to high |

| Priming | Not required |

Submersible Water Pumps

Submersible pumps are designed to be submerged directly into wastewater or sumps, making them ideal for drainage and wastewater handling in treatment facilities.

Common Specs:

| Feature | Specification |

| Flow Rates |

Varied based on pump size

|

| Solids Handling |

Depending on the pump design

|

| Materials |

Stainless steel, cast iron, etc.

|

| Efficiency | Moderate to high |

| Priming | Not required |

High-Pressure Pumps

These high pressure pumps are easy to install and require least maintenance. We have designed such pumps that can operate at low voltage conditions. Such types of pumps are widely used to supply the water in high level buildings. It is a cost-effective solution for high head discharge.

Progressive Cavity Pumps

Our pump experts analyze the volumes of wastewater your generate, the contaminants in the water and the level of purity required, to help you select the ideal pump that minimizes overall operational and maintenance costs while lasting long term. The former pumps must be highly durable and heavy-duty to handle large volumes effectively.

Air-Operated Diaphragm (AODD) Pumps

AODD pumps are versatile and capable of handling various wastewater types, including abrasive or chemically aggressive fluids.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for thick sludge

|

| Solids Handling | Excellent |

| Materials |

Various materials, including plastics and metals

|

| Efficiency |

Variable depends on the design

|

| Priming | Not required |

Grit Pumps

Grit pumps are used for handling grit and sand-laden wastewater in sewage treatment plants. They prevent abrasion and clogging in downstream equipment.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for slurry handling

|

| Solids Handling |

Excellent for high solids content

|

| Materials |

Wear-resistant materials like hardened alloys

|

| Efficiency | Moderate to high |

| Priming |

Often requires priming

|

Chemical Dosing Pumps

Chemical dosing pumps are used for the precise injection of treatment chemicals into wastewater, ensuring effective treatment processes.

Common Specs:

| Feature | Specification |

| Flow Rates |

Precise dosing capabilities

|

| Solids Handling |

Limited (suitable for clean fluids)

|

| Materials |

Various materials, often plastics

|

| Efficiency |

Variable, depending on the dosing method

|

| Priming |

May require priming for initial dosing

|

Slurry Pumps

Slurry pumps are designed for moving abrasive and high-solid-content wastewater in industrial wastewater treatment, such as in mining and mineral processing facilities.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for slurry handling

|

| Solids Handling |

Excellent for high solids content

|

| Materials |

Wear-resistant materials like hardened alloys

|

| Efficiency | Moderate to high |

| Priming |

Often requires priming

|

Grinder Pumps

Grinder pumps are specifically designed to macerate solids in wastewater, making them suitable for sewage and effluent systems.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for thick sludge

|

| Solids Handling |

Excellent for solids maceration

|

| Materials |

Stainless steel, cast iron, etc.

|

| Efficiency | Moderate |

| Priming | Not Required |

Peristaltic Pumps

Peristaltic pumps are ideal for metering and dosing applications in wastewater treatment due to their precise and gentle fluid handling. They use a flexible tube to create a rolling motion, preventing contamination.

Common Specs:

| Feature | Specification |

| Flow Rates |

Precise and adjustable dosing

|

| Solids Handling |

Limited (suitable for clean fluids)

|

| Materials |

Tubing materials compatible with fluids

|

| Efficiency | Moderate to high |

| Priming | Not required |

Screw Pumps

Screw pumps, also known as progressive cavity screw pumps, are used for conveying thick sludges, viscous wastewater, and fluids with high solids content.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for high viscosity

|

| Solids Handling |

Excellent for high solids content

|

| Materials |

Stainless steel, abrasion-resistant materials

|

| Efficiency | Moderate to high |

| Priming | Not required |

Aerators and Air Lift Pumps

Aerators and air lift pumps introduce air into wastewater to aid in the biological treatment process by promoting oxygenation and mixing.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for high viscosity

|

| Solids Handling |

Limited (not designed for solids)

|

| Materials |

Materials suitable for wastewater and air handling

|

| Efficiency |

High for oxygenation

|

| Priming | Not required |

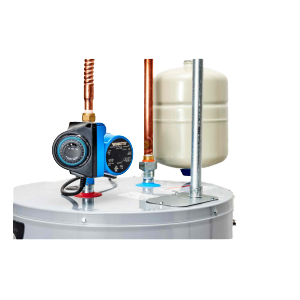

Recirculation Pumps

Recirculation pumps are used to maintain the flow and mixing within treatment tanks or clarifiers, enhancing the settling and separation of solids.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for high viscosity

|

| Solids Handling |

Limited (not designed for solids)

|

| Materials |

Corrosion-resistant materials

|

| Efficiency | Moderate to high |

| Priming | Not required |

Chemical Metering Pumps

Chemical metering pumps are specialized pumps for precise and controlled dosing of treatment chemicals to optimize wastewater treatment processes.

Common Specs:

| Feature | Specification |

| Flow Rates |

Variable, suitable for high viscosity

|

| Solids Handling |

Limited (not designed for solids)

|

| Materials |

Various materials, often plastics

|

| Efficiency |

Variable, depending on dosing method

|

| Priming |

May require priming for initial dosing

|

Applications of Pumps in Wastewater Treatment:

1. Lift Station Pumps: Lift station pumps are used to elevate raw sewage and wastewater from lower to higher elevation treatment facilities, ensuring efficient collection and transportation.

2. Primary Treatment: Pumps are involved in primary sedimentation tanks, aiding in the settling of solids and separation of scum, allowing the removal of heavier solids.

3. Secondary Treatment: In aeration tanks, pumps provide oxygen to support the growth of beneficial bacteria that break down organic matter in the wastewater.

4. Sludge Handling: Pumps are used for the transfer of sludge, both primary and secondary, to digesters and dewatering processes.

5. Chemical Dosing: Chemical metering pumps precisely inject treatment chemicals into the wastewater to optimize coagulation, flocculation, and disinfection processes.

6. Effluent Discharge: Pumps are employed to ensure the controlled discharge of treated effluent into receiving bodies of water or for reuse.

7. Solids Handling: Specialized pumps, like grinders and screw pumps, handle solids-laden wastewater in processes such as screening, grinding, and maceration.

Technological Advancements and Innovations:

1. Smart Pumping Systems: Integration of sensors, IoT, and automation for real-time monitoring and control of pump performance, leading to predictive maintenance and energy efficiency.

2. Variable Frequency Drives (VFDs): VFDs are used to control pump speed, optimize energy consumption, and improve operational flexibility.

3. Sealless Pump Technologies: Innovative sealless designs, including magnetic drives, enhance safety and prevent leaks in chemical dosing applications.

4. Energy-Efficient Pump Designs: Improved pump designs reduce energy consumption, contributing to lower operational costs in wastewater treatment facilities.

5. High-Efficiency Aeration Systems: Advanced aeration technologies, such as fine bubble diffusers, enhance oxygen transfer efficiency in aeration tanks.

6. Advanced Sludge Handling Techniques: Innovations in sludge dewatering equipment and technologies improve the efficiency of sludge management.

Challenges and Solutions:

1. Clogging and Abrasion: Solids handling pumps often face issues of clogging and abrasion. Solutions include the use of grinder pumps and materials resistant to wear.

2. Chemical Compatibility: Selecting pumps compatible with a wide range of treatment chemicals is vital to prevent corrosion. Solution: Use materials suitable for specific chemicals.

3. Energy Efficiency: Wastewater treatment facilities require substantial energy. Solutions include VFDs and high-efficiency pump designs.

4. Maintenance and Cleanability: To ensure compliance with regulatory standards, pumps must be easily maintainable and cleanable. Solution: Choose pumps with hygienic designs and easy disassembly.

5. Sustainability: Environmental concerns drive the need for sustainable practices in wastewater treatment. Solutions include energy recovery systems and advanced treatment technologies.

6. Increased Treatment Capacity: As urbanization grows, the challenge is to expand treatment capacity while maintaining efficiency. Solution: Invest in modern technologies and infrastructure.

FAQ

What are waste water pumps?

Wastewater pumps

For transport of heavily contaminated water which often contains solid particles.

What pumps are used in wastewater treatment plant?

The type of pumps most commonly used at wastewater treatment plants include the centrifugal, progressive cavity, and positive displacement.

What does a wastewater pump do?

A sewage pump is used to transfer sewage liquids and solids from one place to another. Usually, in residential applications, sewage includes soft solids up to 2″ in diameter is pumped from a sewage basin to a sewer system or a septic tank. A sewage pump is installed at the lowest point of the sewage basin.

What is the main purpose of pumping waste water treatment?

What is wastewater treatment, and why is it important?

Wastewater treatment is the process of removing contaminants and pollutants from used water, making it safe for discharge or reuse. It is vital to protect public health, the environment, and ensure the sustainable use of water resources.

What are the key stages of wastewater treatment?

Wastewater treatment typically consists of primary, secondary, and tertiary treatment stages, including physical, biological, and chemical processes to remove solids, organic matter, and pathogens.

How are pumps used in wastewater treatment processes?

Pumps are used to lift, transport, and circulate wastewater at various treatment stages, such as in lift stations, aeration tanks, sludge handling, and chemical dosing.

What types of pumps are commonly used in wastewater treatment facilities?

How can wastewater treatment facilities improve energy efficiency?

What are the challenges in wastewater treatment, and how are they addressed?

What are the environmental benefits of wastewater treatment?

Wastewater treatment prevents water pollution, protects aquatic ecosystems, and contributes to the conservation of water resources, supporting a healthier environment.

How does wastewater treatment contribute to public health and safety?

Can treated wastewater be reused, and for what purposes?

Yes, treated wastewater, also known as reclaimed water, can be reused for irrigation, industrial processes, and even potable water supply in some regions, promoting water sustainability.

How do wastewater treatment facilities ensure compliance with environmental regulations?

Compliance is achieved through careful monitoring, regular testing, and the use of advanced treatment technologies to meet or exceed regulatory standards.

What are the latest innovations in wastewater treatment technology?

Innovations include smart pumping systems, sealless pump technologies, advanced aeration systems, and high-efficiency sludge handling techniques, all aimed at improving treatment efficiency and sustainability.