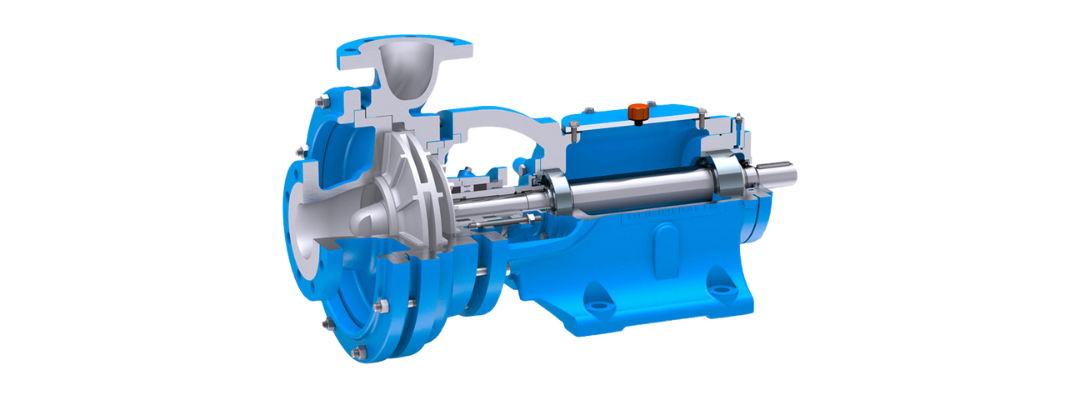

The oil and gas industry relies on robust equipment capable of handling demanding operations, and centrifugal pumps are among the most crucial components. Proper maintenance plays a pivotal role in ensuring the longevity and efficiency of these pumps. Implementing a well-structured maintenance plan and adhering to recommended repair procedures can significantly extend the lifespan of centrifugal pumps and prevent operational disruptions.

Without regular upkeep, centrifugal pumps may develop issues such as internal corrosion, leakage, and mechanical failure, which can ultimately lead to downtime and production losses. To avoid such setbacks, it is essential to follow a structured maintenance plan that includes preventive measures and routine inspections.

Importance of Preventive Maintenance

Preventive maintenance is key to ensuring that centrifugal pumps operate at peak performance for an extended period. A well-planned schedule helps detect potential issues early and prevents costly repairs. Establishing a detailed maintenance plan enables operators to identify problems and implement corrective measures efficiently.

A successful maintenance strategy should include:

- A checklist outlining inspection points based on frequency and priority.

- Step-by-step troubleshooting guides to assist operators in identifying and resolving issues.

- Periodic evaluations of critical pump components to ensure optimal performance.

Regular Monitoring and Inspections

Routine maintenance involves continuous monitoring of key performance parameters to maintain pump efficiency. Essential aspects of pump maintenance include:

- Fluid Levels: Ensuring adequate lubrication and cooling fluids.

- Liquid Properties: Monitoring viscosity and contamination levels.

- Flow Rate: Checking for consistency and identifying flow restrictions.

- Pressure Levels: Assessing suction and discharge pressures to detect anomalies.

- Pump Power Consumption: Evaluating energy efficiency and identifying irregularities in motor performance.

Recommended Maintenance Schedule

Developing and executing a structured maintenance plan ensures the continued efficiency and reliability of centrifugal pumps. Below are key maintenance tasks to be performed at regular intervals:

Daily Checks:

- Inspect for leaks, unusual noises, or vibrations.

- Verify that safety guards and shields are securely in place.

- Monitor motor and pump temperatures.

- Check that operating pressure and flow rates are within the recommended range.

Monthly Maintenance:

- Lubricate bearings as per manufacturer recommendations.

- Clean oilers, sight glasses, and level indicators.

- Remove debris from the pump’s suction strainer to prevent clogging.

- Check the alignment between the pump and motor, adjusting as needed.

Quarterly Inspections:

- Evaluate the pump’s seals for signs of wear or leakage.

- Assess impeller and casing for corrosion, erosion, or mechanical damage.

- Examine wear plates and replace them if necessary.

- Verify the integrity of bolts, couplings, and fasteners.

Annual Overhaul:

- Conduct a comprehensive inspection of all internal pump components.

- Replace worn-out parts, including seals, bearings, and impellers.

- Inspect the pump casing for excessive wear or structural damage.

- Perform a detailed motor evaluation, checking windings and electrical connections.

Enhancing Pump Longevity and Performance

A well-maintained centrifugal pump not only extends the machine’s operational life but also improves efficiency and reduces the likelihood of unexpected failures. To maximize performance:

- Maintain detailed maintenance logs to track inspections and repairs.

- Keep an inventory of critical spare parts to minimize downtime.

- Train personnel on best maintenance practices to ensure proper handling and troubleshooting.

By following a structured maintenance program, you can ensure that your centrifugal pumps remain in peak condition, minimizing operational disruptions and maximizing productivity.