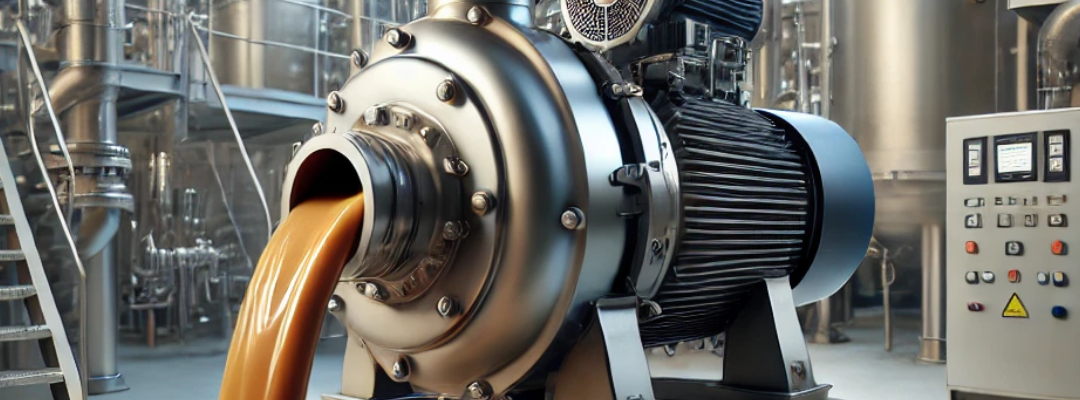

Understanding Molasses and Its Pumping Challenges

What is Molasses?

Molasses is the thick, syrupy byproduct left behind after the crystallization of sugar during the refining process. While it is rarely used in confectionery, it plays a significant role in treacle toffee production, animal feed, fermentation, and biofuel applications. Due to its high viscosity and sticky nature, selecting the right pump is crucial for efficient handling and transfer.

Best Pumps for Molasses: Which One Should You Choose?

Transferring thick fluids like molasses requires specialized pumps that can handle high viscosity, minimize shear stress, and prevent clogging. Here’s a look at the best pump options:

Gear Pumps for Molasses (Best for High-Viscosity Fluids)

Gear pumps are positive displacement pumps that provide non-pulsating, continuous fluid movement. They are an ideal choice for molasses due to the following advantages:

- High efficiency in handling thick fluids

- No friction valves, reducing wear and tear

- Consistent flow rate without cavitation

- Works well with high-viscosity liquids (5,000 – 10,000 centipoise or cps)

Limitations:

Not suitable for pumping abrasive liquids or solids, as particles can cause gear wear.

Rotary Lobe Pumps (Best for Food-Grade Applications)

For industries such as food processing and distilleries, rotary lobe pumps are a great option because:

- They handle high-viscosity fluids smoothly.

- They provide gentle handling, preserving molasses consistency.

- Hygienic and easy to clean, meeting food industry standards.

Consideration:

These pumps require regular maintenance due to their intricate design.

Diaphragm Pumps (Best for Variable Viscosity Applications)

Diaphragm pumps are a good alternative when dealing with varying viscosity levels. These pumps use air or hydraulic pressure to move fluid and are effective for molasses in the following ways:

- No seals, reducing leakage issues.

- Handles both high and low viscosity fluids.

- Can pump abrasive liquids with solids.

Limitations:

Lower efficiency for continuous, high-volume applications.

Molasses Flow Characteristics: What You Need to Know

Since molasses is 5,000 to 10,000 cps, it requires pumps that can handle thick fluids effectively. Below is a quick comparison of viscosity levels and required pump types:

| Fluid | Viscosity (cps) | Recommended Pump Type |

| Water | 1 cps | Centrifugal Pump |

| Molasses | 5,000 – 10,000 cps | Gear Pump / Rotary Lobe Pump |

| Honey | 2,000 – 3,000 cps | Gear Pump |

How Viscosity Affects Pump Performance

Viscosity measures a liquid’s resistance to flow, and molasses exhibits a laminar flow pattern, meaning:

- Fluid moves in concentric layers with no turbulence.

- Lower velocity at pipe walls, higher velocity at the center.

- Requires a volumetric pump with a speed range of 200-2000 rpm to prevent clogging.

Key Considerations When Selecting a Molasses Pump

Before choosing a pump, consider these factors:

- Pump Material: Stainless steel for food-grade applications.

- Flow Rate: A minimum of 10-50 GPM (gallons per minute).

- Temperature Handling: Some pumps perform better at higher temperatures (warm molasses flows more easily).

- Maintenance Needs: Opt for low-maintenance pumps to reduce downtime.

Viscosity and Measurement: Understanding Centipoise (cP)

Viscosity is typically measured in centipoise (cP) or poise (P). Here’s a quick conversion guide:

- 100 Centipoise (cP) = 1 Poise (P)

- 1 Centipoise = 1 mPa·s (Millipascal Second)

- 1 Poise = 0.1 Pa·s (Pascal Second)

- Centipoise = Centistoke × Specific Gravity

Understanding these values helps in selecting a pump with the right flow rate and power for optimal efficiency.